WorkBoat – Seating technology advances as military and commercial demand grows

by Ken Hocke

Ask mariners what the most important part of a workboat is, aside from the hull, and they would probably say the engines or generators, propellers, waterjets, radar, or any number of other pieces of equipment.

But when would they get to seating? Some old timers are reading this and saying to themselves, “We would stand up for our whole 12-hour shift. Old man so-and-so didn’t even have a place for you to sit down. Said he ain’t paying people to sit around all day.”

Well, old man so-and-so is long dead and so are his methods.

In a report released earlier this year by Mordor Intelligence entitled “Marine Seats Market Size & Share Analysis — Growth Trends & Forecasts (2025 – 2030)”, the analysis shows growth in the commercial marine seating market over the next five years.

According to the report, the marine seats size market is valued at $1.82 billion in 2025 and is forecast to reach $2.23 billion in 2030, advancing at a 4.15% compound annual growth rate, a trajectory that signals the sector’s passage from post-pandemic recovery into a maturity phase where ergonomic innovation, weight reduction, and regulatory compliance carry more weight than raw production volume.

“Shipowners are upgrading cabins, bridges, and passenger-area seats to meet tighter vibration and fire-safety rules. At the same time, military and offshore operators seek shock-mitigating solutions that protect crews during high-speed maneuvers,” the report said. “Weight-saving composite frames, embedded sensors, and 3D-printed components enable builders to differentiate themselves on comfort, sustainability, and lifecycle cost. The growing preference for premium finishes in cruise, yacht, and fast ferry builds also supports value growth even as unit shipments level out.”

One aspect of the industry that all the players agree upon is that the seat your boat needs depends on what kind of vessel it is and where it’s operating. “There is no ‘one seat fits all boats,’” said Sean Gerrett, director of sales, Shockwave Seats, Sidney, British Columbia.

MILITARY/LAW ENFORCEMENT

Shockwave specializes in shock-mitigating seating. For now, the military is the company’s primary market. “For military operators, Shockwave’s Drop-Down Bolster seats provide the performance they are counting on to protect them from extreme forces while also offering the ability to stand when the boat is not at speed,” said Gerrett.

Many of the military vessels that have Shockwave seats in them operate in extreme conditions. “The evolution of marine suspension seating over the past 25 years has been informed by ongoing research and feedback from the crews that have been using these seats for an extended period of time,” said Gerrett. “This has brought us to a pivotal moment in this industry where the crews operating in extreme conditions can enjoy the benefits of new technology that will make their mission experiences comfortable and efficient and safeguarding them against long-term injury.”

H.O. Bostrom, Waukesha, Wis., also does quite a bit of work in the military space, supplying seating for police patrol boats, Coast Guard craft, naval fleets, and NOAA vessels. And beyond newbuilds, the company sees steady business coming from service parts and replacement seats in boats already in service.

As far as which Bostrom seats go into most of its military and municipal clients’ vessels, “For the military sector, it’s often a split between custom-designed systems and the SeaPost Sierra T-580,” said Paige Bostrom, H.O. Bostrum’s sales and marketing manager. “Both are built for durability, comfort, and the demanding conditions our military and law enforcement customers face.”

Bostrom said that at its core, H.O. Bostrom is an engineering-driven company. “That means we don’t just provide off-the-shelf seating; we create custom solutions when customers need them. A good example is the work we’ve done for Canadian naval ships, where we delivered tailored seating systems that met precise requirements,” she said.

The company’s lineup includes static helm chairs, shock-absorbing suspension seats like the T-380 and T-580, and a range of options designed to reduce fatigue in high-impact environments. “Our focus has always been on keeping operators safe, supported, and comfortable, and we’re committed to staying at the forefront as seat technology continues to evolve,” said Bostrom.

Norwegian seat manufacturer Norsap has been a DNV-certified supplier to the United States Navy, U.S. Coast Guard, Marine Nationale, and Norwegian Navy and Coast Guard for decades.

“Our Norsap seating business is a fairly even mix between Military vessels, tug and barge, passenger vessels, and the energy industry,” said Caleb Armstrong, commercial product manager at Imtra, the official U.S. Norsap dealer, New Bedford, Mass. “A good chunk also comes from the pilot boat industry which we are proud to support and look to continue to build upon.”

Armstrong said Norsap seats offer their customers a longer life span, and their adjustability allows for a more ergonomic wheelhouse, which leads to an increase in productivity and safety when you buy a Norsap seat. “We hear the same story all the time that operators will buy a cheap helm seat but end up tossing it for a new one after just a few years of use,” said Armstrong. “So, it’s a misconception that the cheapest option up front is going to be the most economical in the long run. Our chairs have been designed for countless years of heavy abuse and are fully serviceable. I often receive inquiries from customers who have had a Norsap chair for 10-plus years and they just want to order a few new cushions to get their chair(s) like new again.”

COMMERCIAL

H.O. Bostrom sells most of its helm chairs in the workboat market — towboats, harbor tugs, and offshore supply vessels. Its best seller on the commercial side is its SeaPost Sierra helm chair. “Customers value its rugged construction, ergonomic support, and adaptability in tough workboat environments,” said Bostrom.

She said that a common misconception in the marine industry is that seats are interchangeable on a vessel. “The reality is every vessel, and application requires the right seating solution. For example, you wouldn’t want to put a low-profile suspension seat on a harbor tug. It would sit too low and wouldn’t give the adjustability that a helm chair provides,” said Bostrom. “That’s why it’s so important for shipbuilders and operators to evaluate the needs of the job. Our sales and customer service teams spend a lot of time working with customers to make sure they get the right seat for their vessel.”

Gerrett said Shockwave has a broad range of seating options that allows it to provide the industry with mission and role specific seating solutions. “Today’s suspension seat buyer has more choices and is generally well informed,” he said. “Where possible, collaboration between the boat manufacture, operator, and Shockwave, leads to the best outcome. Often, we are supplying a 90% commercial off-the-shelf product, but one of our strengths is to provide the 10% custom solutions that will make the difference with boat and mission-specific integration fit and function.”

The Norsap chair made for towboat use is the 1500 series chair that is built on a five-leg base with locking wheels. “This was designed specifically for the inland towboat industry following several design iterations with real world feedback from operators,” said Armstrong. “Several inland towboat companies have adopted the use of this chair, and we’ve gotten nothing but spectacular feedback and hope to continue to grow on that.”

GOING FORWARD

The seating industry can’t afford to sit on its laurels. The marine industry runs 24 hours a day, seven days a week. New vessel designs are coming out of computer programs and companies such as Shockwave, H.O. Bostrom, Norsap, and others have to be ready to keep up with the demands of these new designs while servicing what’s already out there.

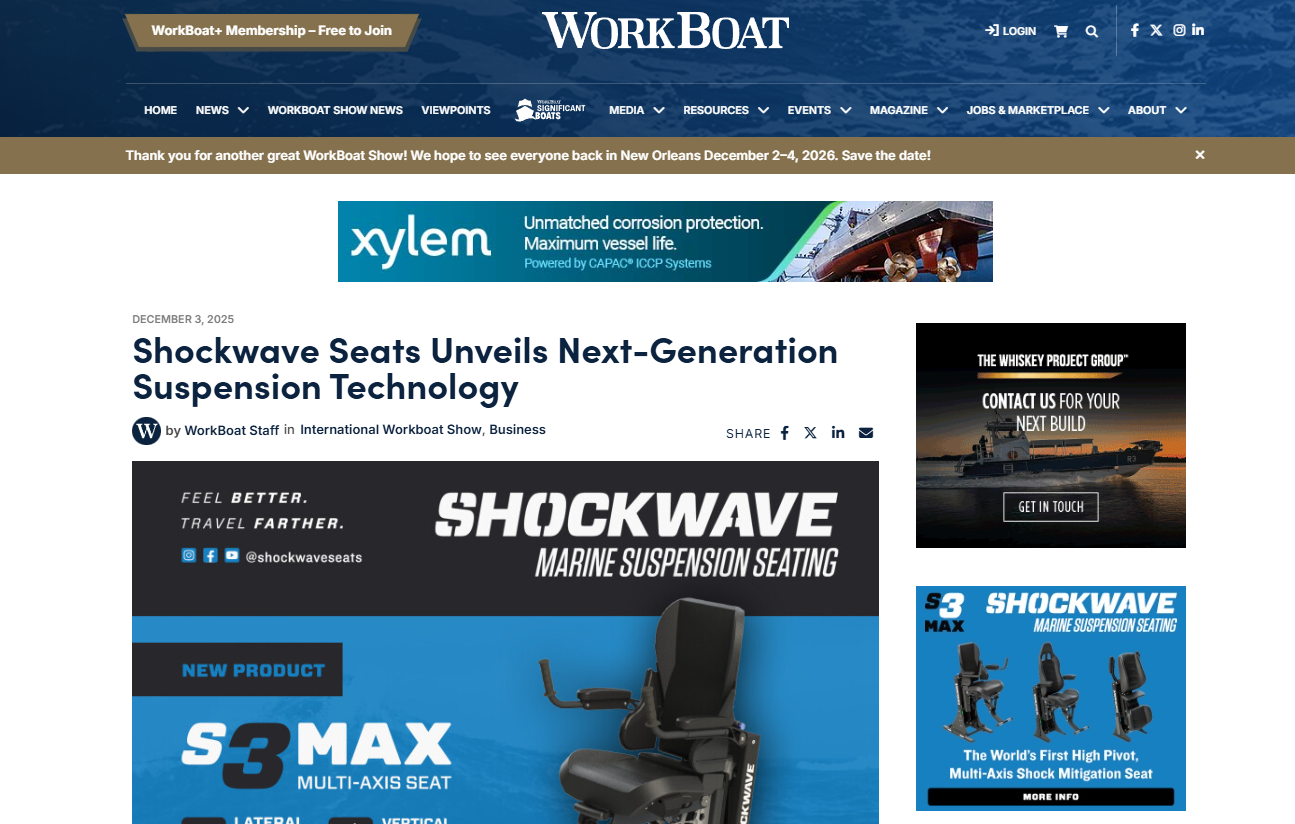

“Multi-axis seating is the future,” said Gerrett. “While existing seats can significantly reduce vertical accelerations, lateral accelerations have not been adequately addressed. Lateral accelerations tend to have less force than vertical; however, the body, neck are not as adept at mitigating those forces. Shockwave will be unveiling the most advanced shock mitigation seat to date at the [International] WorkBoat Show.”

H.O. Bostrom recently launched its Pacifica AL helm seat. The seat is engineered to keep the occupant comfortable with an ergonomic high back, adjustable lumbar support, and a spring system that smooths out the ride. It features an aluminum pedestal. “We’re also exploring expansions to our existing lines, such as wider helm chairs and more premium seating options, because we know comfort and customization are becoming increasingly important,” said Bostrom. “Another significant area for us is shock-mitigating technology; we have some new developments in the pipeline for shock-absorbing seats.”

The Pacifica AL features an aluminum pedestal; pneumatic lift system with 112 lbs. of lift force; molded, high-density foam cushion; 4” diameter stanchion tube; 360° locking swivel; 6” fore/aft travel, locking in 1” increments; reclining back; 4” height adjustment that ranges from 21” to 25” from the floor or 14” to 18” from the floor. There is also an optional footrest.

“We sell a lot into the tug market,” Ron Ogren, H.O. Bostrom’s sales specialist, said during a visit to the company’s headquarters this summer. “It hits a good price point for the customer.”

Armstrong said Norsap’s engineers have come up with several shock-mitigating options that will be on display at this year’s WorkBoat Show (Dec. 3-5) in New Orleans. “This product range has gained traction in the military and high-speed craft markets, and we are excited about the potential,” he said.