FEEL BETTER. TRAVEL FARTHER.

Helm & Crew Seats

The Shockwave S2 provides 6-inches (150mm) of shock travel and can be installed onto a riser or storage box. Its low-profile design makes the S2 a great choice when space is limited or in an enclosed cabin.

- Commercial and Professional Applications

- Comes in High-Back and Mid-Back

- Used on Cabin Boats for Moderate to Heavy Sea Conditions and High Speeds

The Shockwave S3 provides 8-inches (200mm) of shock travel and can be installed with additional options, controls and a footrest mounted directly to the seat. The S3 is a perfect fit for RHIBs or cabin boats. These seats mount directly to the deck.

- Professional and Military Applications

- Comes in High-Back and Mid-Back

- Used for the Most Demanding Sea Conditions and High Speeds

The S6 fills the gap between the S5 recreational suspension range and the S2 professional suspension seats. Designed for light commercial applications, the S6 is ideal for multiple operators of varying heights.

- Ideal for commercial vessels with multiple operators

- Fully integrated height adjust raises the seat 3” (75mm)

- Moderate to heavy sea conditions

S2 Helm & Crew Seats

S2 Helm Seat

- Mid-back: SW-S2-1200

- High-back: SW-S2-1300

S2 Helm Seat - Description

Our best-selling S2 Helm or Passenger Seat offers unparalleled ergonomics for comfort and performance. This Helm Seat can be mounted on a seat riser, storage box or even bulkhead mounted. Commonly used on cabin boats for moderate to heavy sea conditions. Our S2 Helm Seat is available in a Mid-Back or a High-Back version for extra head and neck support.

Height Adjust

Available with Height Adjust:

SW-S2-1200-HA | SW-S2-1300-HA

Suspension Travel

Benefits

- Quick release and simple stowing functions

- Seats can be customized and combined depending on mission or vessel requirements

- Welded aluminum and stainless steel components

- Form-fitting Corbin cushions

S2 Flip Bolster Seat

- Mid-back: SW-S2-1201

- High-back: SW-S2-1301

S2 Flip Bolster Seat - Description

This seat offers a flip bolster, enabling occupants to sit or stand while providing superior ergonomics and performance.

With its low seat mounting height, the S2 Helm Seat fits on top of seat riser-storage boxes in place of traditional truck seats. The S2 Flip Bolster it is a popular choice for cabin and T-top applications. For the helm and nav operators, the optional Fore/Aft Slide and Height Adjust ensure compliance and comfort for a full range of occupants.

Seat shown with Deck Slide, Deck Mount and Armrests.

Height Adjust

Available with Height Adjust:

SW-S2-1201-HA | SW-S2-1301-HA

Suspension Travel

Benefits

- Quick release and simple stowing functions

- Seats can be customized and combined depending on mission or vessel requirements

- Welded aluminum and stainless steel components

- Form-fitting Corbin cushions

S2 Drop-down Bulkhead Mount

- Mid-back: SW-S2-1202-BM

- High-back: SW-S2-1302-BM

S2 Drop-down Bulkhead Mount - Description

This Drop-Down Bulkhead Mounted Seat allows the user to sit or stand while offering superior comfort in both positions. It is commonly used in cabin boats and T-top applications. The Bulkhead Mount provides a clean installation free of trip hazards. Equipped with a 6-inch travel FOX Float H2O custom-tuned and fully adjustable shock absorber. Developed in tandem with FOX Defense and designed for outdoor marine applications.

Seats shown with armrests and bulkhead mounts.

Suspension Travel

6” (150mm) travel FOX Float H2O shock

Benefits

- Quick release and simple stowing functions

- Seats can be customized and combined depending on mission or vessel requirements

- Welded aluminum and stainless steel components

- Form-fitting Corbin cushions

S2 Vessel and Product Application

Government agencies, law enforcement and military vessels, SAR applications

Suited for cabin boats with seat riser or storage box mount

Moderate to heavy sea conditions and high speeds

S3 Helm & Crew Seats

S3 Helm Seat with storage

- Mid-back: SW-S3-1204

- High-back: SW-S3-1304

S3 Helm Seat with storage - Description

Our comfortable S3 Helm or Passenger Seat paired with our performance-leading S3 Suspension; This seat is available with a deck or bulkhead mount and commonly used in cabin boats for the most demanding sea conditions. The storage box below can be utilized for stowing and protecting personal effects.

Seats shown with folding footrests, armrests and deck mounts.

Height Adjust

Available with Height Adjust:

SW-S3-1204-HA | SW-S3-1304-HA

Suspension Travel

Benefits

- Quick release and simple stowing functions

- Seats can be customized and combined depending on mission or vessel requirements

- Welded aluminum and stainless steel components

- Form-fitting Corbin cushions

S3 Flip Bolster Seat with storage

- Mid-back: SW-S3-12014

- High-back: SW-S3-13014

S3 Flip Bolster Seat with storage - Description

This seat is a versatile Flip Up Bolster for seated or standing occupants, paired with our performance-leading S3 Suspension. It is commonly used in cabin boats for the most demanding of conditions. The storage box below can be utilized for stowing and protecting personal effects.

Seats shown with folding Footrests, Armrests and Deck Mounts.

Height Adjust

Available with Height Adjust:

SW-S3-12014-HA | SW-S3-13014-HA

Suspension Travel

Benefits

- Quick release and simple stowing functions

- Seats can be customized and combined depending on mission or vessel requirements

- Welded aluminum and stainless steel components

- Form-fitting Corbin cushions

S3 Drop-down Bolster Seat

- Mid-back: SW-S3-T1202-FF2

- High-back: SW-S3-T1302-FF2

S3 Drop-down Bolster Seat - Description

The S3 Drop-Down Bolster is our most popular and versatile helm seat. With a simple pull handle the drop-down bolster converts from a seated to standing bolster. When equipped with the integrated folding footrest (optional), the footrest stows & deploys automatically with the base cushion. The optional bulkhead mount provides a clean installation free of trip hazards.

Applications include center console RHIBs for the most demanding users and applications. Shockwave’s drop-down bolster is also the workhorse of the USCG fleet with over 1500 units in service on the Response Boat Small II.

Suspension Travel

Equipped with an 8-inch (200 mm) travel FOX FLOAT H20 custom-tuned and fully adjustable shock absorber. Developed in tandem with FOX Defense and designed for outdoor marine applications.

Benefits

- Quick release and simple stowing functions

- Seats can be customized and combined depending on mission or vessel requirements

- Welded aluminum and stainless steel components

- Form-fitting Corbin cushions

S3 Vessel and Product Application

Military missions, law enforcement, pilot & patrol boats

Suited for center console and T-top applications

The most demanding sea conditions and high speeds

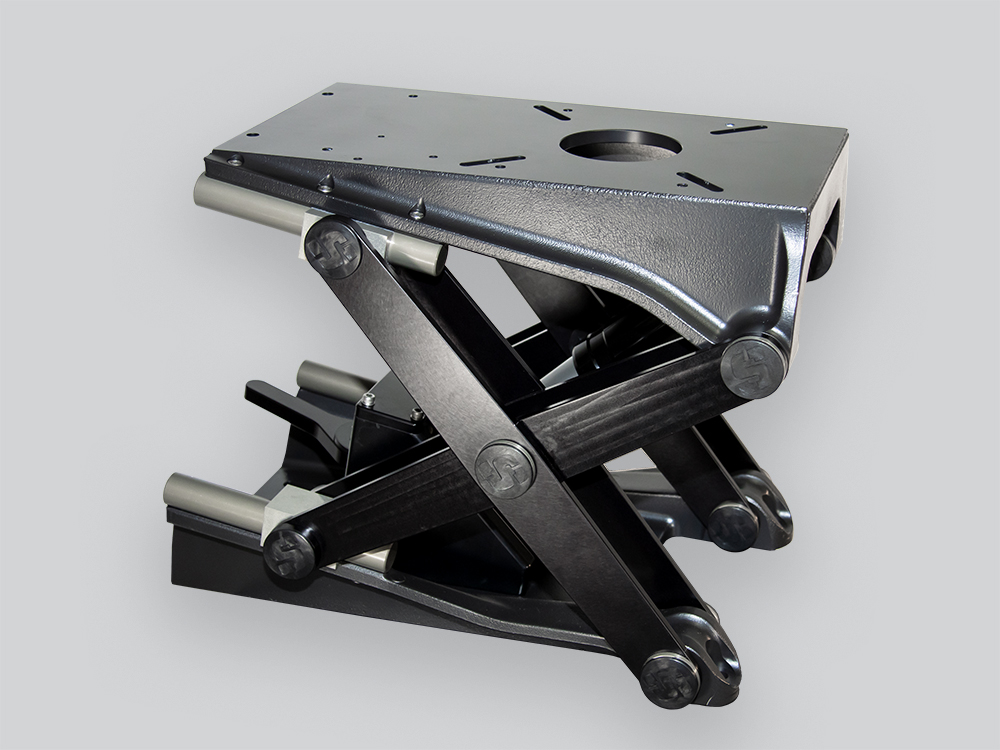

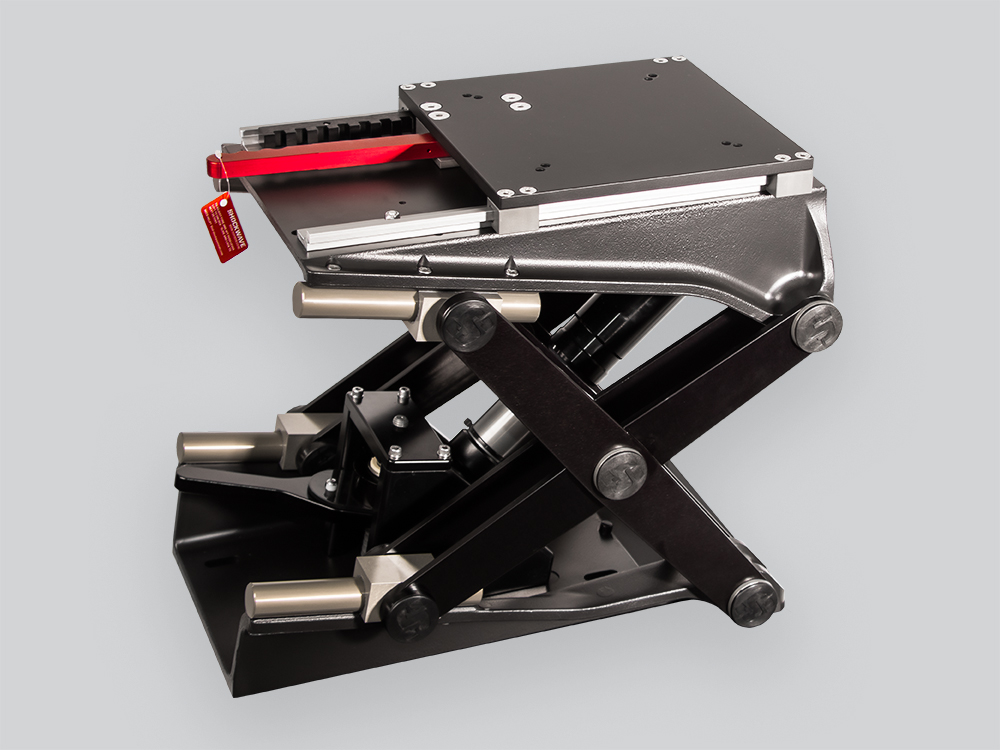

S6 Suspension Base

S6 Suspension Base

SW-07366

S6 Suspension Base - Description

The S6 fills the gap between the S5 recreational suspension range and the S2 professional suspension seats. Designed for light commercial applications, the S6 is ideal for multiple operators of varying heights in moderate seas. The S6 suspension base provides 5.5” of travel for occupants up to 300lbs. Universal bolt pattern allows for pairing with many common seats on the market.

Dimensions

- Height: The factory height setting is 11” (279 mm), with 3” (76mm) upward height adjustment;

- Width: 12” (306 mm)

- Length: 17.75” (451 mm)

Suspension Travel

Weight Capacity

Accessories

- Slide (SW-07867)

- Swivel Slide (SW-07863) for S5 Corbin mid back and high back seats, or a non-Shockwave seat

- Swivel (SW-07865) with swivel shield

- S5 Corbin seats: Mid-back (SW-04920-B) and high-back (SW-06328-B)

Availability

Limited supply, once these bases are sold out they will no longer be available.

Features

- Integrated height adjust raises the seat 3” (75 mm)`

- Designed for moderate sea conditions and operating environments

- Finished in black and engineered to eliminate corrosion points

- Custom tuned FOX Float 3 shock absorber offering 5.5” (139 mm) of travel

Benefits

- Pairs ideally with a Shockwave S5 Corbin Seat or use an existing seat

- Easy access to fill valve in all height positions

- Integrated height adjust offers consistent suspension performance in all positions

- Optional accessories include the S6 swivel, slide, or swivel/slide

S6 Vessel and Product Application

Designed for light commercial applications, including search and rescue, crew boats, pilot boats, fisheries and government agencies.

Reach out to our sales team if you have any questions about this product: Please fill out this form for an inquiry or call 1.778.426.8545

excellent support

We provide direct support in person, on the phone or by email as required or requested. We also have technical engineering support available to travel in person to help with installation training or other requirements as they arise. Real humans helping real people.